关于贝博bb官网(中国)股份有限公司

公司专业生产整体井、井盖、管材、雨污排等产品,欢迎来电咨询

玻璃钢整体井系统一站式服务

贝博bb官网(中国)股份有限公司,位于国家黄蓝两大经济区核心地带——东营市经济技术开发区东凯工业园,占地面积12000平方米,注册资本6亿元,公司固定资产投资3000万元,年生产能力2亿元,现有职工50余人,其中专业技术人员15人。

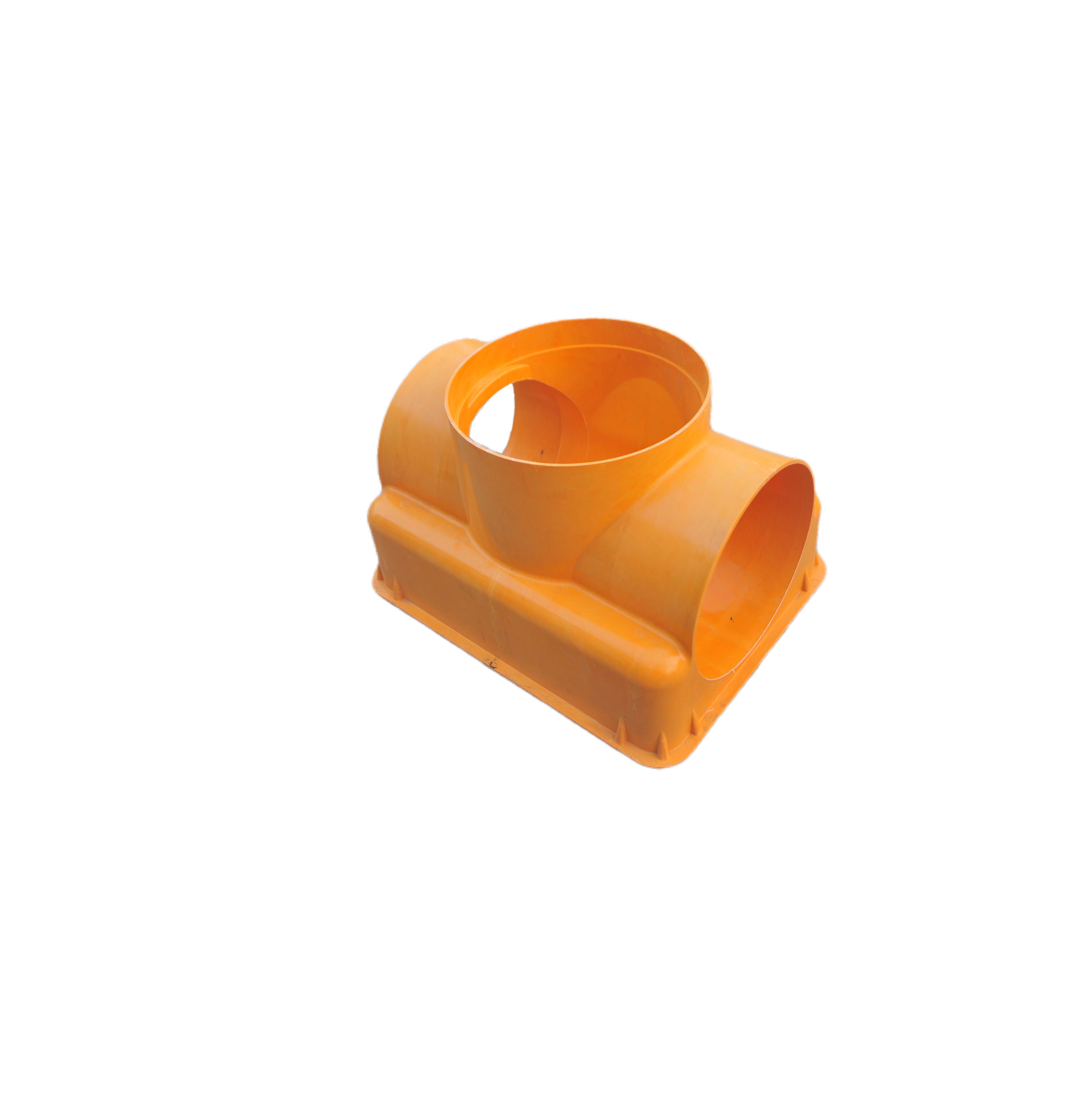

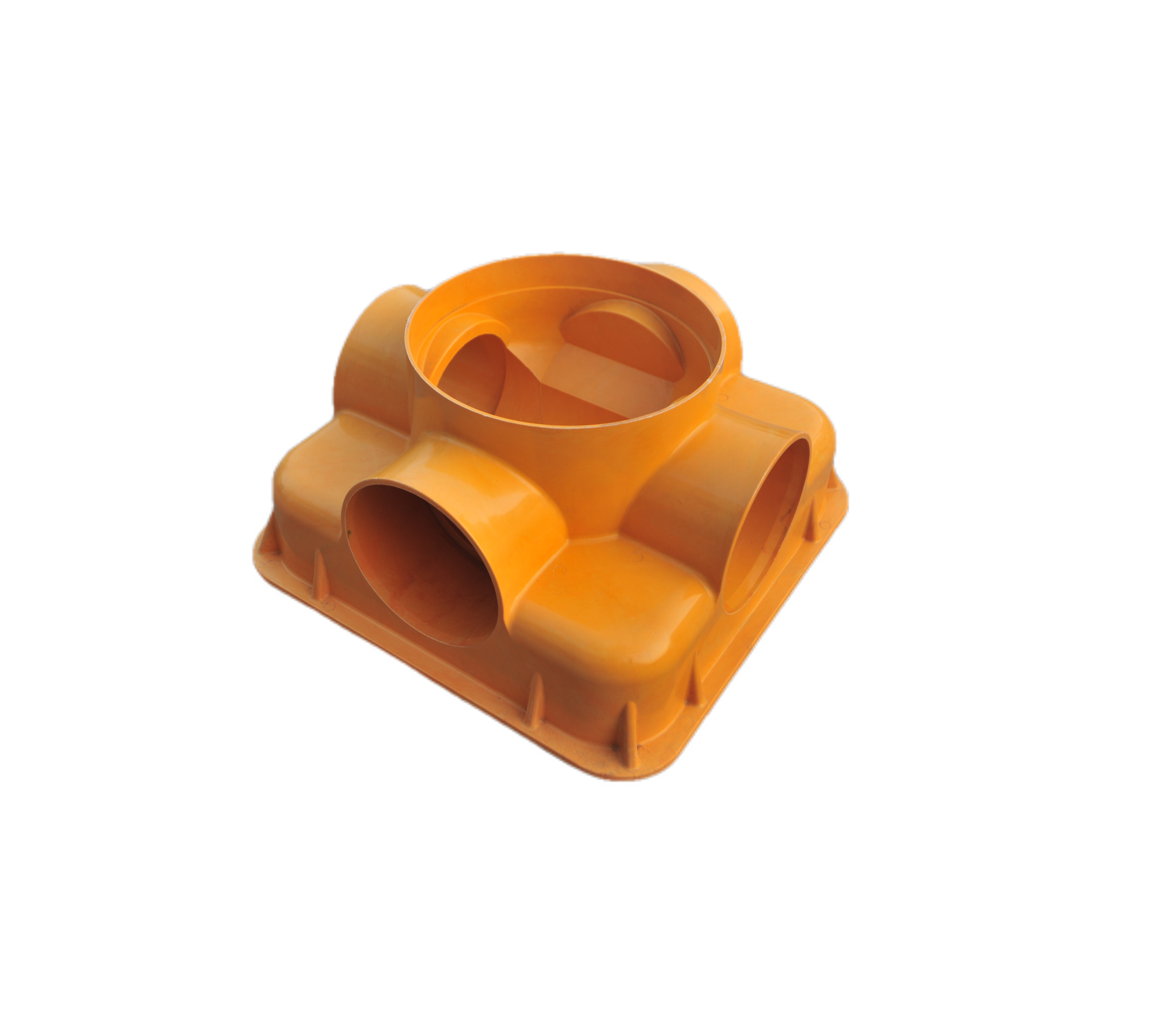

公司主要生产雨污排放系统系列产品(SMC玻璃钢高强井盖、SMC玻璃钢整体检查井、各种整体箱体、HDPE中空壁缠绕排水管、HDPE双壁波纹排水管、HDPE双平壁中空立钢高环刚度缠绕排放管、玻璃钢化粪池、雨水收集及污水处理系统等)。

科技是第一生产力。公司秉承“质量为先,不断创新”的市场理念,研发了多款实用型产品,1、玻璃钢复合整体检查井 2、玻璃钢复合加强筋 3、SMC仿大理石玻璃钢井盖 4、HDPE平封口全钢带波纹排放管。

新闻中心

公司专业生产整体井、井盖、管材、雨污排等产品,欢迎来电咨询

2023

02-20

2021

01-15

贝博bb官网(中国)股份有限公司全体职工恭贺新春

2021

01-15

贝博bb官网(中国)股份有限公司诚招区域代理

2021

01-12

本报探访武汉大道整治沿线城区积极反应

2021

01-12

井箅安装说明

2021

01-12

井盖外观验收标准

贝博bb官网(中国)股份有限公司微信公众号

欢迎关注我们的官方公众号

代码勿动

发布时间:2021-01-15 08:16:34

客户留言

客户留言

描述:

Copyright © 2020 贝博bb官网(中国)股份有限公司 All Rights Reserved 官网网站建设:中企动力 淄博 编号:鲁ICP备08109821号